Description

Fire resistance:

up to 240

Seals: pipes, cables &

air ventilation ducts

Primer:

not required

Fast Drying: fully set

within 1 hour

Sound reduction:

Rw 48-64 dB

Service life:

Minimum 30 years

(You need to be logged in to download some documents)

- Used alone or with FR Pipe Wrap or Service Coating FR-1

- Brush away dust and debris in the opening. Dampening surfaces improves adhesion

- All exposed metal in contact with the mortar must be protected against corrosion

- Mix powder into water – not the other way around

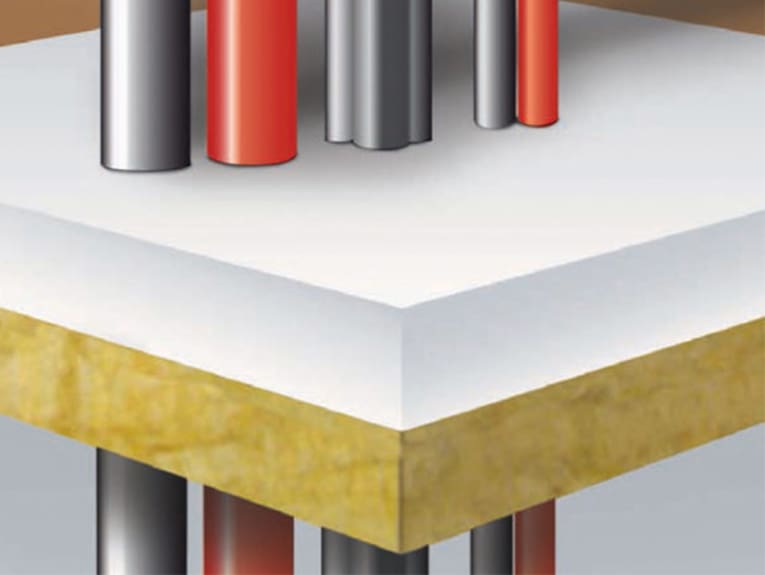

- Firestops most pipes and cables in concrete floors

- Also tested for angled metal pipes (90–45°)

Application properties:

- Application temperature: +5 °C to +50 °C

- Set time: under one hour

- Fully cured after 30 days

Installation Video

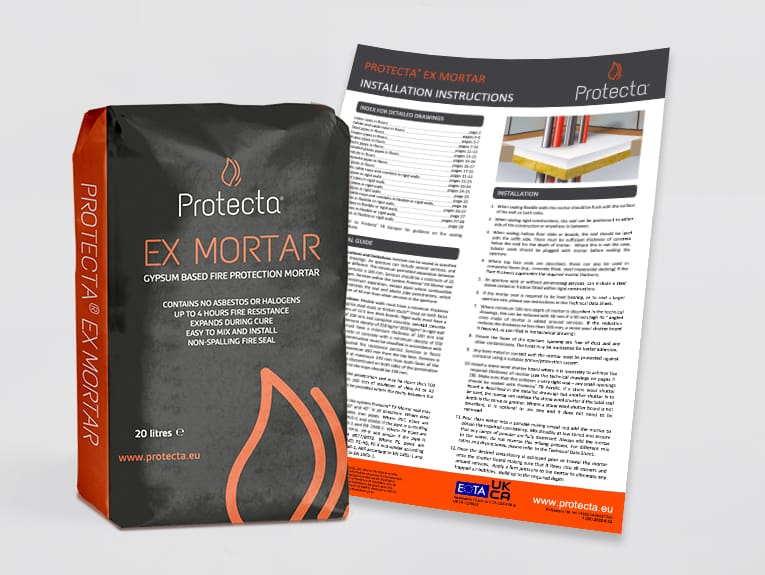

Protecta EX Mortar is a castable fire-rated compound, supplied as a dry powder and mixed with water to create a strong, durable seal. Designed for sealing service penetrations in fire-rated floors, it also helps maintain the building’s acoustic insulation and airtightness.

During curing, the mortar slightly expands to create a secure bond around service penetrations and the surrounding structure, ensuring a tight and lasting seal.

Typical applications include:

- Firestopping cables, pipes, and mixed services in floors

- Hospitals, schools, commercial buildings, and technical service areas

The mortar is simple to mix and apply, dries quickly, and leaves a smooth, off-white finish that can be sanded, drilled, or painted if required.

For wall penetrations, we recommend using Protecta FR Board for the most efficient and documented firestop solution.

What is the maximum opening size EX Mortar can be used in?

Without reinforcement, EX Mortar can be used in openings up to 1,200 × 2,400 mm.

With reinforcement bars, larger openings can be cast up to 2,600 × 3,600 mm.

Additionally permitted:

- 1,200 mm width × 12,000 mm length

- ≤ 800 mm width × unlimited length

For reinforced solutions with reinforcement:

- 1,800 mm width × 18,000 mm length

- ≤ 1,500 mm width × unlimited length

All dimensions require the system to be installed according to approved details. See documentation for depth, shuttering, and reinforcement requirements.

Can I reduce the depth of EX Mortar?

Yes, in solutions with a specified minimum depth of 100 mm, it can be reduced by 50 mm if a 50 mm high gypsum mortar cone is formed around the services at a 45° angle.

Note: If this results in a total depth below 100 mm, a mineral wool board must be used as backing.

Which pipes and cables is EX Mortar approved for?

Protecta EX Mortar is tested and approved with:

- Cables and conduits

- Steel pipes

- Copper pipes

- Alupex pipes

- LK Pal Universal pipes

- PVC, PE, and PP plastic pipes

- Composite pipes

- Polybutylene pipes

- PEX pipe-in-pipe systems

See the installation guide for dimensions and details.

Can steel sleeves be used in openings when using EX Mortar?

Yes, openings with or without penetrations may contain a steel sleeve – either embedded or friction-fitted in solid structures. The sleeve must be protected against corrosion before firestopping with EX Mortar.

In which types of structures has EX Mortar been tested?

Protecta EX Mortar has been fire tested in the following structures:

- Concrete and masonry walls

- Gypsum walls

- Concrete and masonry floors

It can also be used in hollow core slabs and ribbed decks.

Is the product resistant to moisture and frost?

The mortar must cure in dry conditions and be protected from frost. In humid environments, Protecta Waterproofer must be used.

Protecta FR Acrylic has European Technical Assessment ETA 22/0748 – issued under EU Regulation 305/2011, based on EAD 350454-00-1104.

The product is tested according to EN 1366-1, -3, -4 and -12, with reference to EN 1363-1.

All Protecta products are proudly developed and manufactured by Polyseam Ltd. To meet the demanding standards of modern construction, we continuously invest in rigorous testing and development in collaboration with leading laboratories.

EX Mortar is documented to have low environmental impact and long service life.

- Minimum 30-year service life – reduces waste and replacements

- Environmentally safe installation – free from hazardous emissions

- Suitable for environmental building projects – meets BREEAM 6.0

- Environmental Product Declarations (EPDs) available – covers the full lifecycle from raw material to disposal

Useful Links

Here are some quick links to guide you through your fire protection journey with Protecta